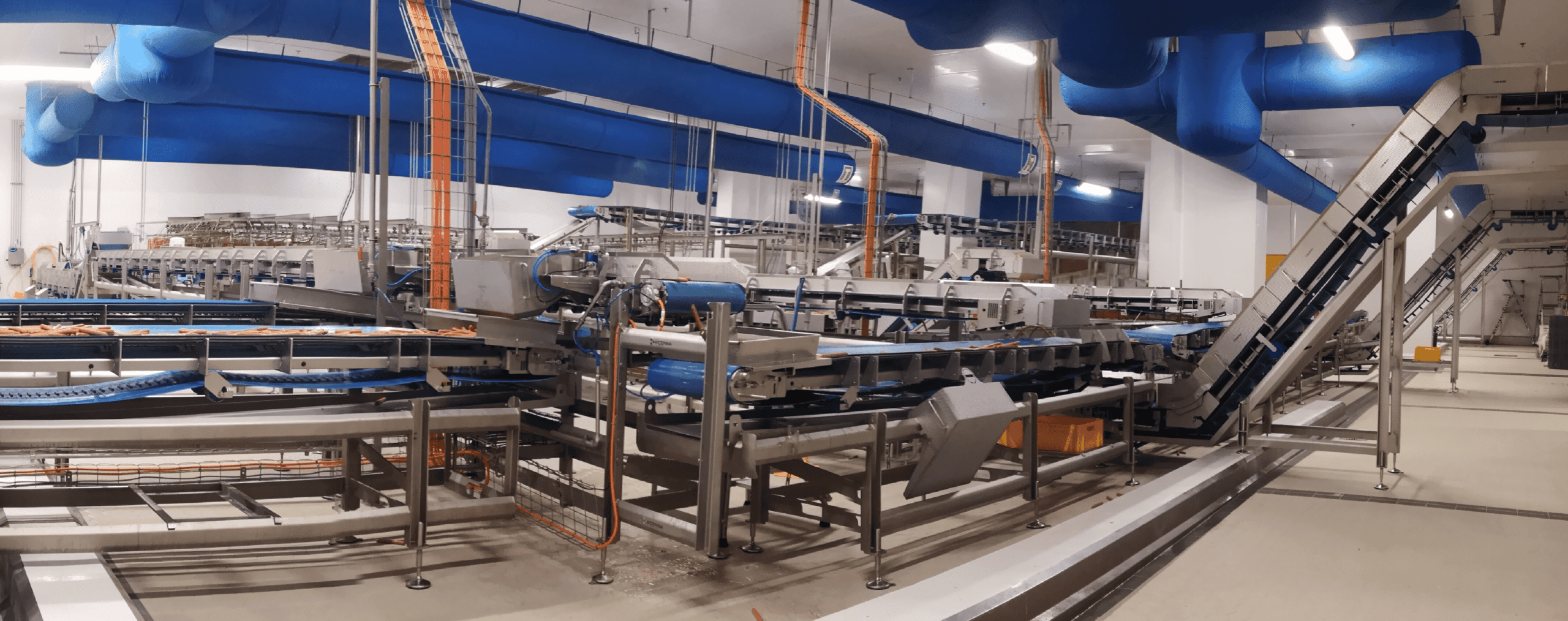

Nous concevons et réalisons

des solutions intelligentes et sur mesure

Au cœur de

nos conceptions

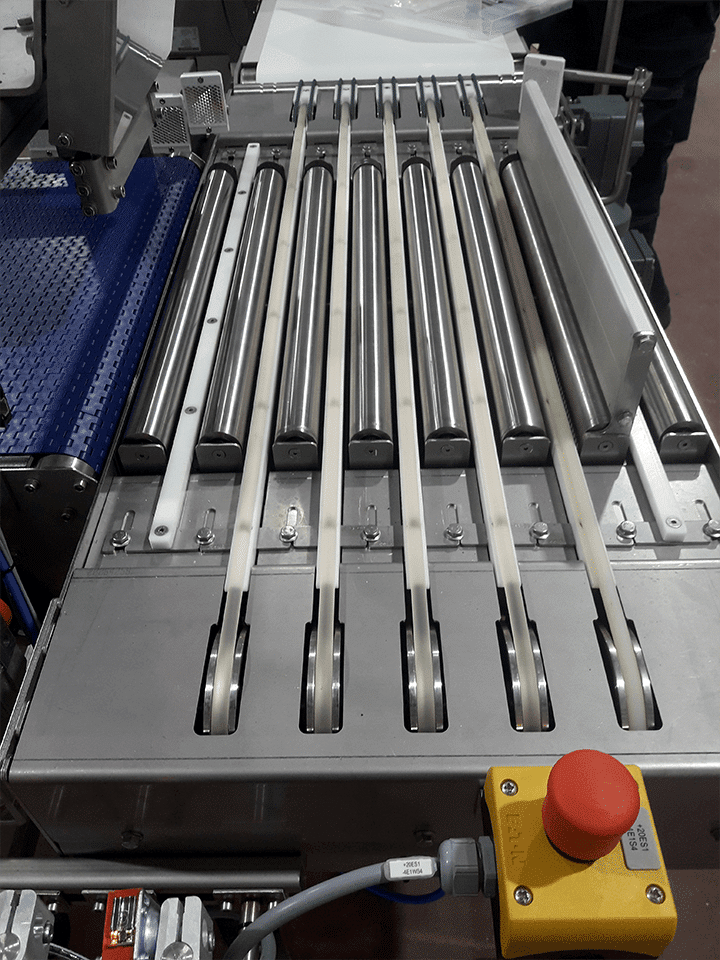

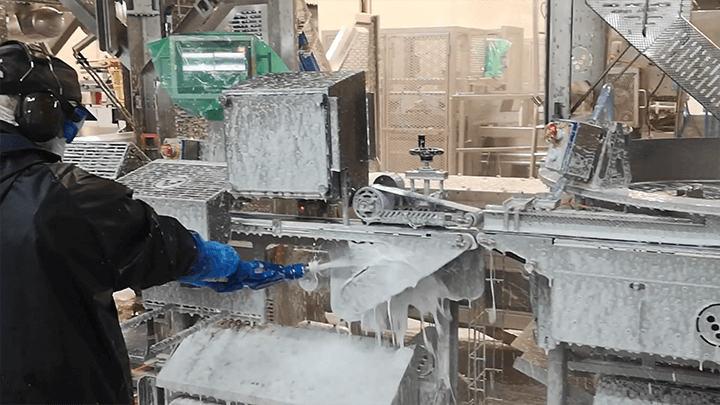

Expertise Hygiène

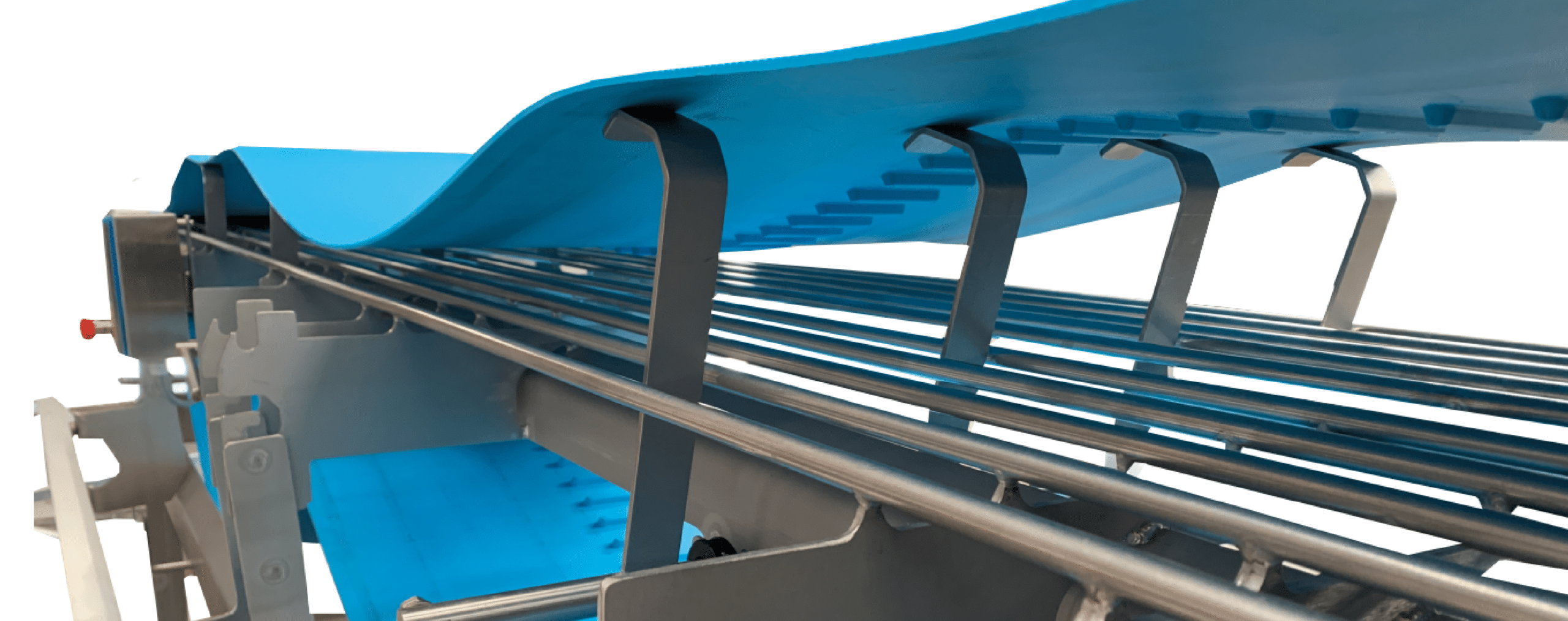

Le secteur agroalimentaire nécessite des équipements répondant aux plus hautes exigences en termes d’hygiène, c’est pourquoi Acemia conçoit chaque solution pour répondre à vos besoins en matière de lavage, d’absence de zones de rétention, avec des matériaux compatibles au contact avec les produits alimentaires.

Nos équipements sont fabriqués en inox 304L ou 316L. Nos convoyeurs peuvent être équipés de détente rapide de bandes et de releveurs pour faciliter le nettoyage de l’intérieur du châssis. Des rampes de lavage avec buses inox peuvent être équipées côté intérieur et extérieur de bandes. Des solutions CIP (Cleaning In Place) peuvent être également proposées.

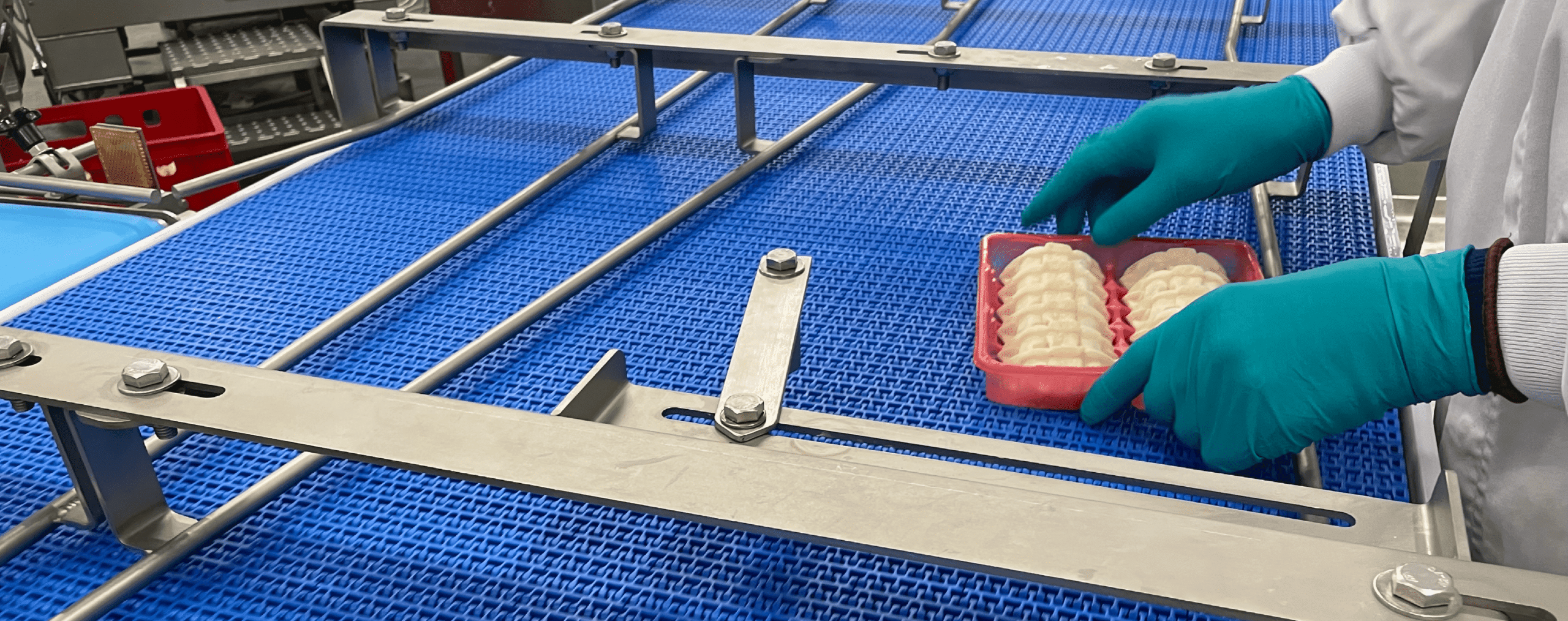

Expertise Ergonomie

Acemia apporte un soin tout particulier dans la conception des postes opérateur. En effet, l’ergonomie de ces postes est très importante pour réduire les risques de TMS. Nous travaillons en étroite collaboration avec des ergonomes, vos représentants ou encore la CARSAT. L’optimisation des mouvements et l’ergonomie du poste permettent de réduire la pénibilité pour les opérateurs et sont gage d’efficacité accrue de vos lignes.

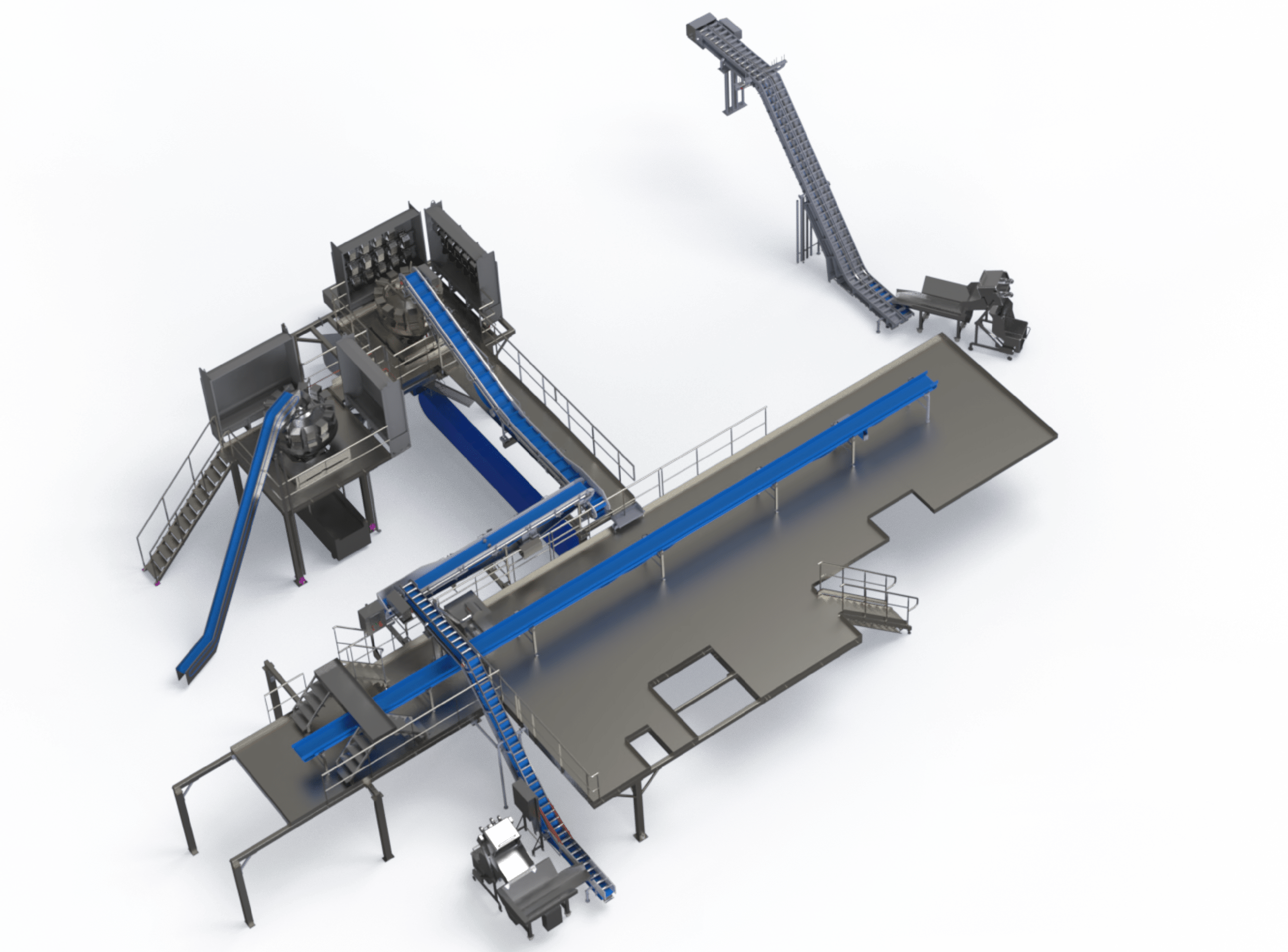

Conception sur mesure

Acemia adapte et conçoit des solutions spécifiques pour chaque client. Les solutions élaborées par nos experts tiennent compte des contraintes d’encombrement, des cadences maximum demandées, des spécificités liées aux produits nus ou emballés, et des autres critères clé de votre cahier des charges.